MASTER STONEMASONS SINCE 1840

A family-owned company that can go back some seven generations to the early 1840s with its roots originating in Kingston Upon Hull in the United Kingdom, and not simply as monumental stonemasons and master stonemasons, but also of professional sculptors creating many public as well as personal works of art.

For more than fifty years we have been substantially involved in the quarrying and production of Indian Absolute Black granite initially for the global monument industry and since the 1980s for the commercial and retail decorative surfaces trade.

Absolute Black Granite

Absolute Black Granite is a very dark grey to black small-grained Dolerite of the Precambrian period quarried near Warangal and Khammam, Southern India. It has been quarried extensively since the 1960s and is one of the most popular Absolute Black granites in the World.

The quarrying area is on the Deccan Plateau, Southern India.

When using polished Absolute Black granite for large project areas it is recommended to specify the granite from the same quarry supply and factory production facility since the granite background colour may differ plus the factory will have a consistent polishing standard which can easily differ to other potential producers. These differences could be simply the origin of the polishing machines or types of abrasives used to generate the gloss polish.

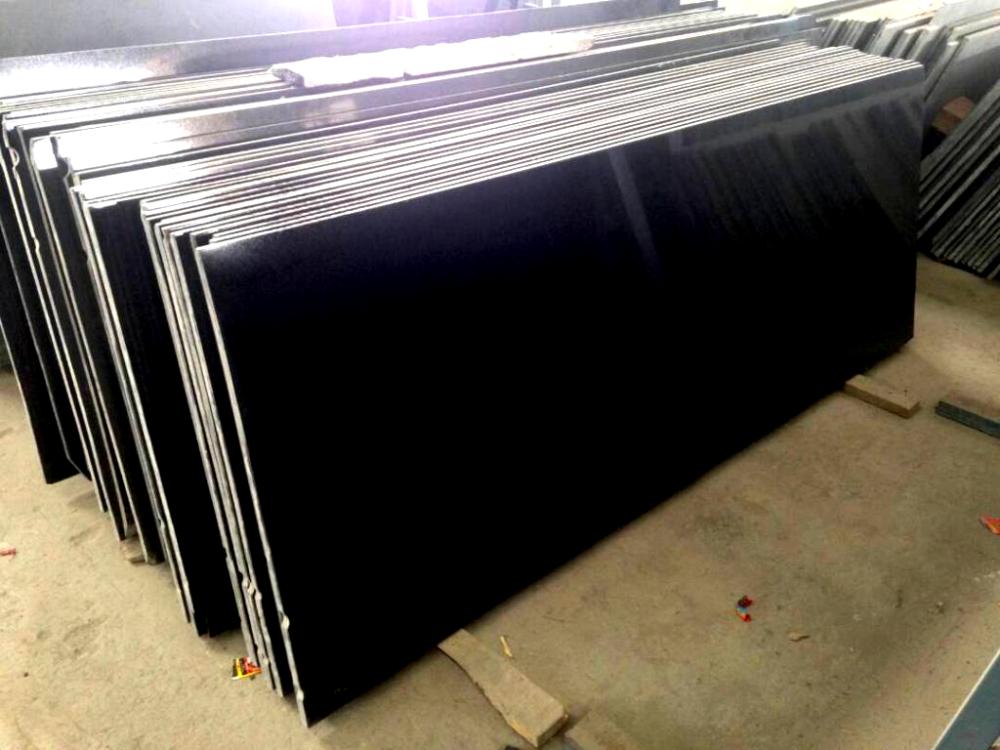

Dimensioned Slabs

For project work we can supply already produced to your sizes or select suitable random-sized slabs for your own production. Please let us know precisely your specifications. When sourcing slabs for your own production to specific smaller measurements it is not neccessary to purchase the larger jumbo slabs, a cost saving may be had by using cutter slabs of precisely the same quality. These slabs re produced from smaller quarry blocks from the same quarry. Quite simply not all blocks quarried are extracted at a large size owing to the quarry's natural characterics.

Absolute Black Granite Slab Sizes

Jumbo Slabs 2 & 3cm: When available 3000+mm x 2000+mm

Large Gangsaw Slabs: 2800mm & above x 1800mm & above

Medium Gangsaw Slabs: 2200mm & above x 1200mm & above

Vertical Cutter Slabs: 2200mm & above x 600~900mm

It must be noted that when suitable blocks are available we can produce slabs of 3200 mm x 2000 mm (126" x 79") however these will be very expensive and especially so when the rarer and much more expensive Premium quality is requested.

A reasonable cost saving can usually be made when buying slightly smaller gangsaw slabs say 2600+ mm x 1400+ (102" x 55") and bear in mind that these are still large, heavy slabs weighing 220+ Kgs in 20 mm and 330 kgs in 30 mm (485 lbs & 730 lbs). When ordering crate loads of slabs it is important that you tell us the maximum weight crate you can handle safely since we normally pack 3~4 tonnes per crate.

Absolute Black Granite Cutter Sawn Slab Sizes

Depending upon the finished slab sizes one requires, cutter sawn sizes can represent a huge cost saving and especially so for kitchen worktops / countertops. Cutter sawn slabs are produced from the same quality blocks as the gangsawn slabs, quite simply they are the smaller blocks extracted at the same time from the quarry. These slabs are traditionally exported at 2400+ mm x 600~900 mm (95" x 24"~36") however if your requirement is for a shorter length, say 1200 mm x 600~900 mm (48" x 24"~36"), then even a bigger cost saving may be achieved.

Cutter slab crates are usually about half the height of gangsawn slab crates therefore expect three or four more crates per Full Container Load (FCL) yet more slabs per crate. These crates are invariably much easier to unload from a container and also are subject to much less in-transit damage. If the majority of your requirements are for producing cladding, flooring or strips, then this could be your best cost-saving solution.

Black Granite Types

There are hundreds of different Black Granite quarries throughout India however the vast majority of them are not of Absolute Black since they may have different coloured backgrounds, flecking and veining or, quite simply, do not have a dense black mirror finish when polished. The actual black granite may be perfectly suitable for most uses and especially so when not requiring a polished surface and can be a huge cost saving.

Owing to the popularity of Absolute Black Granite some suppliers will attempt to dye their stone. To check for dying try the lemon juice or acetone test. Do ensure that the granite is washed clean before doing this otherwise it may simply be general dirt. Take a clean white rag and apply some lemon juice or acetone to the granite surface. If any residue or black appears on the rag then it has been dyed. Also, if you have several small sample choices, leave a drop of the lemon juice for five minutes on the polished surface, wipe the surface clean and observe the results, once again any dull spot or patch and the material has been doctored.

Absolute Black Granite Slab Inspection Video

We can accommodate any inspection service whether be it yourselves or a suitably qualified independent company.

Our inspection is included in the slab cost whereas an independent company may charge upwards of USD 300.00 for this service. It is very important to note that any independent company needs to be fully briefed as to your expectations since they are normally very experienced with this type of work and understand the Absolute Black Granite agreed standards.

Petrography

Dolerite (Diabase, Microgabbro): A dark-coloured, medium-grained igneous rock which contains plagioclase feldspar of labradorite composition and pyroxene of augite or titanaugite composition as essential minerals, and magnetite, titano-magnetite, or ilmenite as accessory minerals. Where olivine also occurs as an additional mineral, the rock is termed an "olivine dolerite". Where quartz occurs as an additional mineral in the groundmass, the rock is termed a "quartz dolerite". Dolerites are the medium-grained equivalents of basalts and, like the basalts, can be divided into alkali and tholeiitic types. Dolerites are commonly found in shallow level intrusions such as dykes, sills, or plugs.

Absolute Black Granite Technical Specification

Compressive Strength: 3011/kg cm2

After Freezing: 2636/kg cm2

Ultimate Tensile Strength: 280/kg cm2

Water Absorption: 0.00001

Volumetric Weight: 2989 kg/m3

Hardness (Moh's Scale): 6-7

Note: These figures and details are given for guidance purposes only, no reliance should be taken as to their accuracy.

Synonyms

Dense Black, Jet Black, Nero Assoluto Indiano, Super Black

Absolute Black Granite Usage

Whilst Absolute Black Granite is used for many, many kitchen countertop projects and bathroom vanity tops the overwhelming majority of Absolute Black Granite is processed into calibrated tiles, paving, construction projects and since the 1960s memorials have been exported globally. Obviously a polished surface is the most common surface finish to bring out the best colours in the granite plus the glossy surface gives a great contrast to all types of accessories such as taps, sinks or cabinet door handles. Absolute Black Granite is also suitable for flamed (thermal), honed, river-washed, leather and brushed finishes. To learn more about these please go here.

Owing to its natural close-grain formation, it is most unlikely that a sealant can be applied to Absolute Black Granite.

Absolute Black Granite Durability

It is very hard-wearing, very durable and highly moisture resistant with a low maintenance cost however when used as a flooring material in high traffic areas, like all flooring materials, it can be subject to scratching from road and pavement dust and the worst of all is sand dust and that will have an effect on any surface!

Absolute Black Granite Supplies

Full Container Loads (FCLs) Only

An FCL Of Natural Stone Will Hold Between 18-27 Tonnes Depending On The Port Of Unloading